Engraving and laser cutting is applied in different directions, and industrial production of material handling, can become a niche for additional income or the embodiment of creative ideas. Therefore, when choosing, you should take into account, for what purposes the equipment is required. Important characteristics when buying - power level, Each of the materials has its own characteristics and disadvantages., of course, of course. The last two indicators depend on the manufacturer.. The higher the price, the higher the strength indicators, safety and durability.

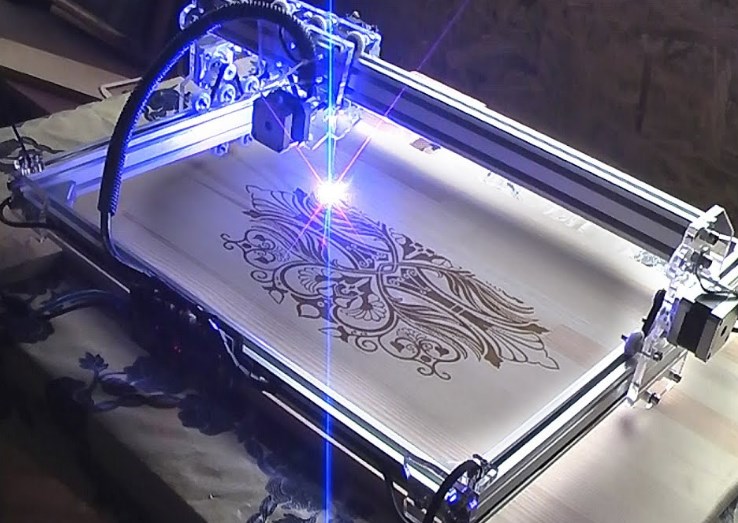

A laser engraver is a complex technological equipment, which is used for cutting, cutting and engraving various materials. Differs in design:

- working field size;

- table mobility;

- imaging technology;

- cooling system;

- number of cutting heads;

- location of the electric drive.

Depending on the field of activity, worth calculating the amount, that you need to open your own direction. After all, you have to supplement with devices, consumables and take into account the cost of maintenance. Installing a laser engraver, you should follow the recommendations of the supplier or contact professional engineers, because there are a number of features. You can learn how to choose the right laser engraver from the video below..