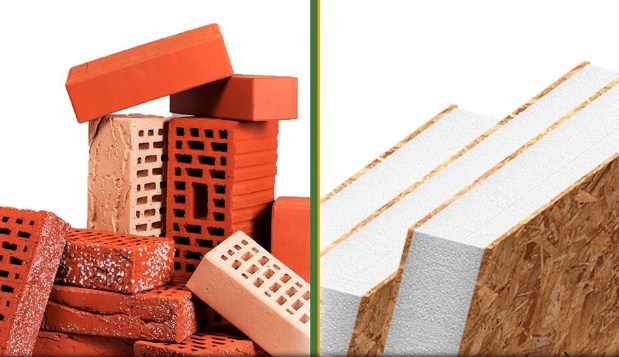

Construction technologies and, properly, materials for the construction of suburban housing there is a huge variety. but, the most frequently built houses in the Stavropol Territory, are country cottages made of bricks and frame-panel board sip panel houses. I want to say in advance, what order a turnkey sip house can be in the company of Fazenda. Let's try to compare the two data, completely different construction technologies, having considered all their most pronounced pros and cons.

Two types of brick are used for the construction of cottages: ceramic and silicate. Both the one and the other kind, its structure is hollow and full-bodied. At the same time, starting the construction of a country house, often there is a dilemma, what kind of brick to use for the main load-bearing walls.

The difficulty in choosing the type of brick comes down to the following points:

- Use hollow or solid bricks. If we compare two walls made of hollow and solid bricks, thick in 240-250 mm, that is - into a brick, then the strength of the walls in both cases will be almost the same. but, the thermal insulation qualities of solid bricks are much lower, than hollow. And here the first dilemma arises - to use hollow bricks for load-bearing walls and, after raising the walls, produce sand-cement plaster, or use solid brick with subsequent insulation of the facade with expanded polystyrene or mineral wool slabs. There is also a third option - to use hollow clinker bricks and remove the facade surface with clean masonry, however, the price for it is about 3 times higher, than an ordinary ceramic stone. All three of these options, carry, anyway, large financial costs: or plaster, or insulation with expanded polystyrene, or clean masonry, but exorbitantly.

- Use ceramic or sand-lime bricks. Silicate brick almost in 2 times cheaper than ceramic. However, sand-lime brick imposes a lot of weight. With almost the same dimensions, 1 a piece of sand-lime brick weighs about 400-1000 gram more ceramic bricks. If silicate brick is chosen for the construction of a country house, then the monolithic foundation tape should be deeper and more massive. It turns out a paradox, or build from expensive ceramic bricks on a standard strip-type buried foundation, either build from cheap sand-lime bricks on an expensive reinforced concrete foundation.

- Hygroscopicity of silicate bricks. Silicate brick, although in 2 times cheaper than ceramic, has one significant drawback - high hygroscopicity. Simply put, sand-lime brick pulls the enemy very strongly, which can lead to dampness of the walls and even their premature destruction under the influence of temperature changes and subsequent weathering. This leads to the fact, what cash, saved on the purchase of sand-lime bricks, subsequently spent on finishing the facade. As a result,, the gain from such construction is minimal.

For the construction of a frame country house, ready-made SIP panels are used, differing in lining material and heat-insulating layer. Despite, that there is a huge variety of CIP panels, in Russia the following panels are most popular:

- OSP + PSB + OSP;

- OSP + MV + OSP;

- FL + PSB + FL.

It's worth saying right away, that unlike a brick house, a one-story house made of vulture panels begins to win from the very beginning of the construction process. Whichever type of the above panels is used, anyway, the total weight of a frame-panel house will be much less than a dwelling built of bricks. Consequently, for the construction of a frame house, there is no need to manufacture an expensive buried strip foundation. Most often, the construction of a house using self-supporting insulated wire technology is carried out on a shallow tape or generally pile-screw foundation.. Construction on pile-grillage and columnar foundations is not excluded.

In addition to significant savings in time and financial investments in the manufacture of the foundation, the subsequent benefit from construction directly depends on the type of SIP panels, used in load-bearing walls. Recall, that you can build a sip house in the Fazenda construction company.

- Application of SIP panels OSB + PSB + OSB is considered the most cost-effective. The panel board is lightweight, good thermal insulation and low cost. As a heat-insulating layer in the panel, a sheet of suspended non-pressed polystyrene foam is used, that is, a sheet of medium-sized porous foam. Oriented strand board - OSB is used as a paneling, which has good strength.

- Using OSB panels + MV + OSB in comparison with the previous type will cost significantly more. In the design of this SIP panel, a mineral wool slab is placed between the OSB outer cladding. Besides the high price, at panels, consisting of MB, there are several serious design drawbacks. Over time, insignificant shrinkage of mineral wool can be observed in the thickness of the shield walls, which can lead to, that cold bridges can form on the plane of the wall - areas on the load-bearing wall with poor thermal insulation.

- Panel sandwich panels FL + PSB + FL are characterized by, that in their design, instead of OSB, fiberboard is used, which the, mainly, was introduced into the frame-panel technology with only one purpose - to reduce the flammability class of SIP panels. The cost of these SIP panels is much higher than the cost of the two types described above., wherein, it is also worth considering the greater weight of fiberboard compared to OSB.

Giving a brief description of the most popular SIP panels, we can come to the conclusion, what is the cheapest cost of turnkey construction from SIP OSB panels + PSB + OSP. And such moments as the flammability of this material, can be easily compensated by installing all electrical wiring in special corrugated tubes or gutters.