Tubular heating elements are the most commonly used heating elements.. Used to work both in the air, liquid, gaseous medium and in solids. In their action, they can give off the heat generated in the heater by conduction., convection or radiation.

General characteristics

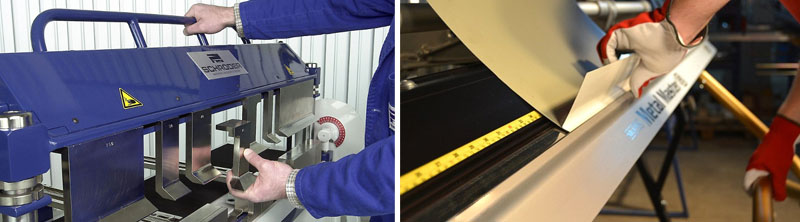

Tens can be of any shape, as a direct, and defined by the customer or device designer. They are built from the appropriate heating element, it can be a resistance wire coiled into a spiral located in a protective tube, in which the material is correctly selected for the working conditions. Heating coil insulated with magnesium oxide (MgO). Magnesium oxide at high temperatures has very good dielectric properties (great resistance) and has a high thermal conductivity.

note! In order to improve the latter characteristic in the process of manufacturing a heating element, magnesium oxide is subjected to compaction by vibration..

Each of the two ends of the tubular heater, for technological reasons has an electrical connector. Electrical connection can be made, e.g. with high temperature resistant connector. In addition, at the ends of the heating element, there may be mechanical fastenings of the heater to the body of the desired device..

Tubular electric heaters for liquid service

Teny Fastov These are heating elements., which, depending on the type of material being heated, can be made in the form of a heater in a tube made of ordinary or nickel-plated copper, stainless steel or other material, resistant to the influence of the heated liquid. They are used to heat water, aqueous solutions, oils and other process fluids, both standing and flowing.

If we are talking about a heating element used for heating, it must be with 100% hermetic fastening. Thus, these heaters must be mechanically fastened in the form of a threaded hole.. The use of appropriate gaskets is also obvious..

Besides, depending on the working conditions in a particular environment, the respective surface loads of the heater must be taken into account.

note! In some cases, these heaters can be part of the heating system., which is a group consisting additionally of a thermostat triggered by the temperature of the liquid and a pump.

Depending on demand and/or heating capacity, they can be made as single-phase or three-phase.

Tubular electric heaters for operation in air and gases

Heating elements required for operation in air or non-flammable gases, characterized by a body made of heat-resistant steel, usually made from tubing of standard diameter 8,5 mm. In some cases, when there is such a need, manufacturer ODO Electric heater can also produce heaters with a diameter 7,2 mm.

Tubular heating elements made of stainless heat-resistant steel have an upper operating temperature limit of approx. 600°C, should be designed like this, so that their load on the surface does not exceed 4 w/cm2. It means, that in the case of a tubular heater with a diameter 8,5 mm, running in the air without forced flow, with a long 1 meter power should not be more than about 1000W.

In order to increase heat loss from the heating element, you can use a heater with a radiator, which naturally increases the heat dissipation area, which automatically lowers the operating temperature. In the case of using forced air circulation, the surface of the heater can be increased by approx. 2,5 fold.

obviously, that the service life is related to the operating temperature of the heating element, therefore, in order to prolong its service life, it is necessary to provide for temperature limitation by selecting a surface load suitable for the conditions of use and the environment, and it is not necessary to consider in the device the cooperation of the heater with the temperature controller.

Tubular heating elements for working in solids

Most often, these electric heaters are made in a case made of stainless heat-resistant steel., and their load on the surface is of the order of 2 to 10 w/cm2. They are used to heat a straight block of metal of a certain shape.. It can be matrix plates, welding plates, etc.. d.

A source: http://elektronagrevatel.com