The process begins with measuring the territory, perimeter along which the fence will be built. If it is decided to install it from a profile sheet, then you need to decide, what should be the height of the sheets and pillars themselves, and also how much. This takes into account the width of the spans and the depth of soil freezing. Important, that the distance between the posts should not exceed 3 m, otherwise the design will be extremely flimsy. On average, this indicator is 2-2,5 m. And the depth of concreting the pillars ranges from 0,8 to 1,5 m. It all depends on the climatic zone.

Selection of building materials.

- Pillars. so, the selection of metal poles begins. All possible natural surprises must be considered: strong winds, cold winters, etc.. d. Square tubes are commonly used. Ordinary pipes can be used, with wall width 2-3 mm. Taken three meters high, considering that, that the meter of the pipe will be concreted. It is best to weld pipe ends securely, to avoid moisture ingress and further corrosion. Also, for some pipes, plugs are sold.. But the best option is laser cutting of metal Chelyabinsk offers a number of manufacturers. And you can also do this using electronic welding., with elements of metal pieces.

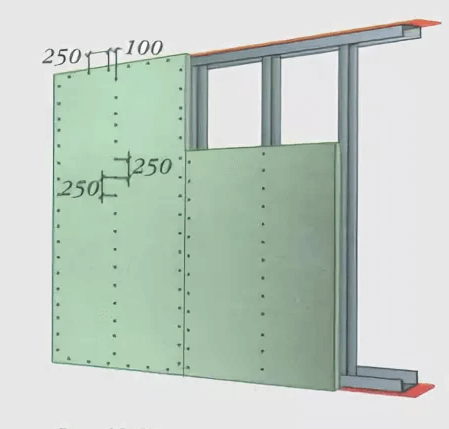

- Lies (streaks). When choosing veins, the profile pipe will fit perfectly, which is quite inexpensive and widely used in the construction of strong fences. Decent construction option.

- Profile sheet. Huge variety, the market is completely packed with these products. In this case, a profile metal sheet of the C8 brand will be used.. Has a fairly acceptable thickness and price range. The color of the leaf should be chosen according to the surrounding landscape.. This is purely a matter of taste.. In addition to profiles, self-tapping screws for metal with a length of about 33 mm. They must match the color of the profile sheet.

Concreting pillars.

Pits are being pulled out, sandy is laid on the bottom, gravel pad. Pillars are installed using a plumb line or level. Then the process of pouring concrete takes place., with crushed stone elements. Dilute the cement mortar strictly according to the proportions and bring to a homogeneous consistency. Should not be too thick and, on the contrary, very liquid. This is an important criterion, which is worth considering. The hole is filled in layers, rammed periodically.

Welding process to posts.

After the period of sufficient drying of the concrete has ended (15 days), welding begins. Here you need to have some skills and abilities in this area.. Otherwise, you need to trust high-level specialists.. The conductors are securely welded to the metal posts, also using level, for a flat construction.

Painting stage to avoid corrosion.

certainly, important point, which will greatly increase the durability of the entire fence, and will also give an aesthetic look. A primer with a high quality level is suitable for this.. All metal parts of the fence are painted, several layers are applied.

The final stage of the installation of profiled metal sheets.

Again, using a plumb line or level, the profile sheets are screwed onto self-tapping screws. This requires gloves., to avoid cuts, since they are very sharp and, of course, you need a screwdriver. Profile sheets are overlapped with each other.

It is important to install firmly, in the process of being swayed by the wind, the structure may be damaged. The result will be wonderful, strong and durable fence, which will serve for many decades and will reliably protect the site from uninvited guests.